FUTURE GOALS & OBJECTIVES

Market Growth

Expanding client base nationally and internationally by building a reputation for quality and reliability.

Technological Advancement

Continuous investment in research and development to integrate innovative manufacturing techniques.

Environmental Responsibility

Committing to sustainable practices, including waste reduction and eco-friendly materials.

Workforce Development

Fostering a skilled, empowered workforce by investing in training and professional development.

Client-Centric Approach

Enhancing customer experience through improved service delivery, transparent communication, and customized solutions.

Heavy Fabrications

Specialists in heavy fabrication, U N Fabricator provides comprehensive solutions for industries requiring durable, high-strength components.

- Custom fabrication solutions for various industrial components.

- Precision handling of high-grade materials, ensuring quality and safety.

- Exceptional durability and reliability.

- Solutions tailored to specific industry requirements, from construction to energy.

Equipment Manufacturing

U N Fabricator manufactures a diverse array of industrial equipment, designed for maximum efficiency, durability, and performance.

Custom-built reactors with high-pressure and hightemperature capabilities for chemical industries.

Precision-engineered for effective thermal transfer, minimizing energy costs.

Turnkey Projects

Project Management Expertise

Project consultation, design, and execution for industries such as oil & gas, chemical, and infrastructure.

Coordinated management, from planning to completion, ensuring adherence to timelines and budget constraints.

Skilled workforce and advanced tools to manage even the most complex project requirements.

Piping Systems And Skids: Integrated Industrial Solutions

U N Fabricator Piping Systems and Skids are designed to streamline installation, improve efficiency, and enhance mobility within various industrial environments. Our solutions combine precision-engineered piping systems with custom-built skids to offer a flexible, reliable, and highly transportable option for complex process setups.

Piping Systems

Our piping systems are crafted with a deep understanding of industrial requirements, focusing on durability, safety, and regulatory compliance.

With expertise in a range of materials such as stainless steel, PVC, and copper, we design robust piping networks that meet the specific needs of industries like oil & gas, chemicals, and manufacturing.

Our skilled team ensures meticulous installation, adhering to strict quality standards to ensure optimal performance and leak-free operation.

Skids

U N Fabricator skid-mounted units are engineered for easy transport and installation, reducing downtime and offering a modular solution for various industrial processes.

Our skids integrate process equipment, piping, and instrumentation into compact, pre-assembled units that simplify on-site setup and maintenance. These skids are ideal for both temporary installations and permanent facilities where modularity and transportability are key.

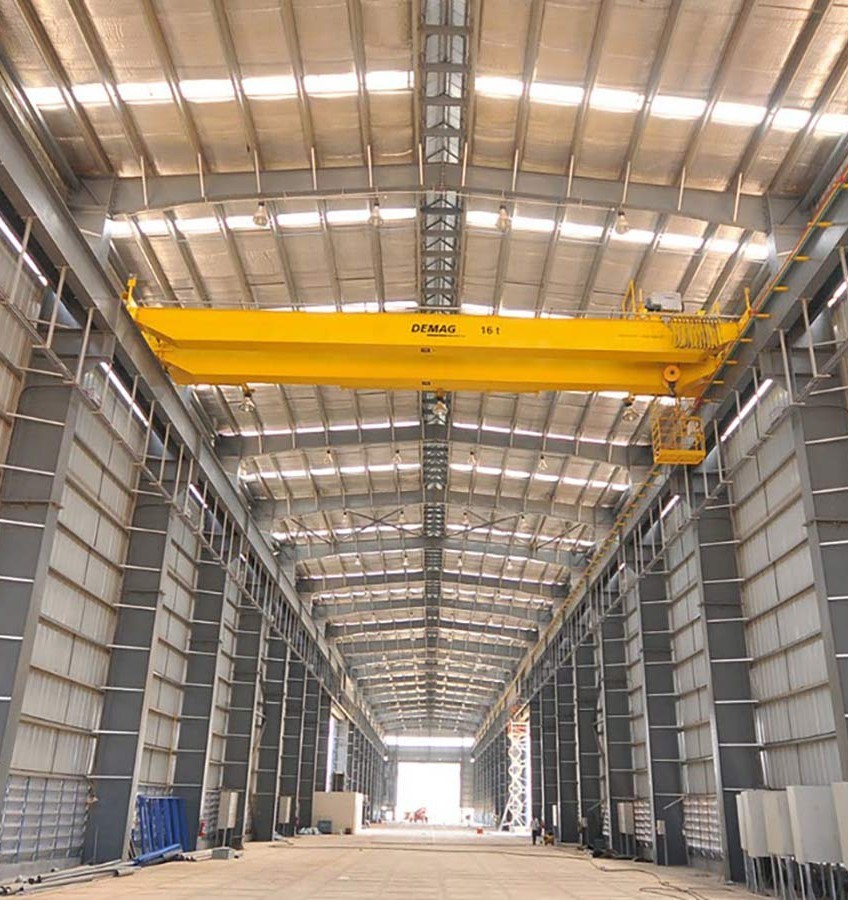

Prefabricated Industrial Sheds

U N Fabricator Prefabricated Industrial Sheds provide a versatile and durable solution for industries in need of reliable, adaptable, and cost-effective spaces. Engineered with highquality materials like galvanized steel and reinforced polycarbonate, these sheds withstand tough weather conditions, corrosion, and daily wear, making them a low-maintenance and longlasting option.

Our prefabricated sheds are fully customizable to meet unique operational needs, whether for manufacturing, warehousing, workshops, or temporary storage facilities.

Clients can personalize dimensions, ventilation, insulation, skylights, and access points, ensuring a tailored solution for specific applications.

Prefabricated components manufactured off-site allow for quick, efficient on-site assembly, reducing installation time, labor costs, and minimizing disruption to ongoing operations.

Turbine casing welding

Turbine casing welding is a process that repairs damage to the casing of a turbine by welding it with a matching metal filler. The casing is heated to a high temperature in a furnace, and the weld is performed with a shielded metal arc or metal inert gas (MIG) weld.

Process

Assess the residual stress levels in the casing

Perform a shielded metal arc or MIG weld with a matching metal filler Heat the casing to a high temperature in a furnace Perform a stress relief operation.

Considerations

The exact temperature depends on the alloy, the procedure, and the application The welding process must be performed by a skilled contractor High levels of residual stresses in the casing can cause distortion and hot cracking Techniques such as grinding and peening can reduce residual stresses Bolting the casing halves together before placing them in the furnace can control distortion.

Applications

Repairing eroded areas, such as horizontal joints, flow guides, and diaphragm inner and outer rings and joints Welding fabricated stainless steel liners inside of crossovers, seal areas, and inlet flow areas of casings.

With their modular design, U N Fabricator sheds can be expanded, relocated, or reconfigured as needed, offering unmatched flexibility for growing businesses. In addition, prefabrication techniques lower material waste and support environmentally sustainable practices, making these sheds an eco-friendly choice that also maximizes return on investment. Built to meet or exceed industry safety standards, these sheds incorporate fire-resistant materials and structural supports, making them suitable for high-demand industrial environments.

Market Growth

Expanding client base nationally and internationally by building a reputation for quality and reliability.

Technological Advancement

Continuous investment in research and development to integrate innovative manufacturing techniques.

Environmental Responsibility

Committing to sustainable practices, including waste reduction and eco-friendly materials.

Workforce Development

Fostering a skilled, empowered workforce by investing in training and professional development.

Geographic Reach

Serving major industrial hubs across India, with a growing footprint in international markets.

Clientele

Trusted by a mix of government projects, MNCs, and large industrial corporations, underscoring U N Fabricator reliability and industry reputation.

OUR MARKET

A focus on diverse sectors, including: